Competition Engine Development (CED) – September 20th-21st

About Course

Student Ratings & Reviews

The class delves deeply into the engineering principles that govern the performance of racing engines, ensuring that participants leave with a thorough understanding of the fundamental dynamics at play. This includes both theoretical knowledge and practical, hands-on training to solidify these concepts. The course is structured around intensive classroom instruction and interactive workshops, creating a well-rounded educational experience for all attendees.

Airflow Dynamics and Combustion Science

One of the core topics of the course is airflow management and its critical role in engine performance. Students will explore how air moves through the intake and exhaust systems, and how modifications can lead to better volumetric efficiency. This is particularly important for naturally aspirated engines, as improving airflow is one of the primary ways to increase engine performance, but also applies heavily in forced induction applications where rules may limit the allowable boost.

Using flow bench data and other diagnostic tools, students will learn how to measure airflow and understand the impact of different components such as intake manifolds, throttle bodies, and cylinder heads. They’ll also cover the effects of camshaft profiles, valve timing, and lift/duration on airflow.

Specific emphasis on understanding the lobe profiles of the cam and how they affect the entire valvetrain performance and how to select profiles for various applications,

In addition to airflow, the course covers the intricacies of combustion. A competition engine must optimize the air-fuel mixture, ignition timing, and combustion efficiency to achieve peak power output. Students will learn how to analyze and adjust these variables to optimize engine performance under various operating conditions.

During these sessions, students will learn how to interpret dyno data, including horsepower, torque, and air-fuel ratios, and make necessary adjustments to improve engine performance. They’ll also get to see actual combustion pressure data from measurements taken from real competition engines.

Spintron Technology for Valvetrain Development

Another unique feature of the Competition Engine Development class is the introduction to Spintron technology. The Spintron is a high-tech machine used to study valvetrain dynamics, an essential component of high-performance engine development. Using this technology, students can analyze how the valvetrain operates at different engine speeds, identify potential weak points, and make improvements to avoid issues like valve float or lifter collapse.

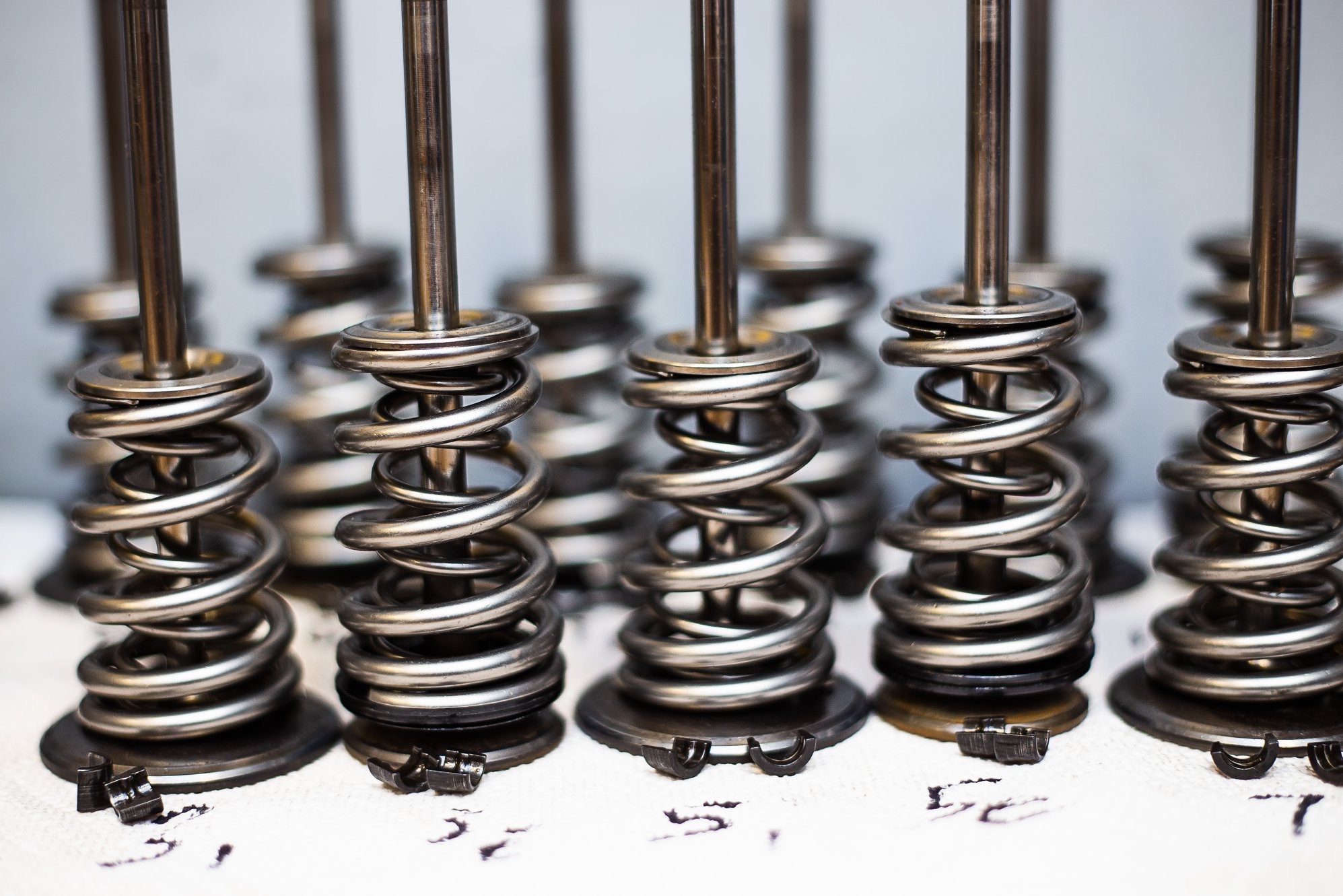

Understanding the valvetrain is crucial in racing engines, where revving to high RPMs is often necessary to extract maximum power. By using Spintron data, students can optimize components like camshafts, rocker arms, springs, and retainers to ensure that the valvetrain can handle the rigors of high-performance operation.

Component Selection and Engine Assembly

One of the most important aspects of building a competitive engine is selecting the right components. The class covers in detail how to choose the best parts for your engine build, considering factors like displacement, intended use, and budget.

Topics include selecting the right block, pistons, connecting rods, crankshafts, and cylinder heads, as well as understanding how each of these components interacts to create a powerful, reliable engine.

In addition to selecting parts, students will learn about the importance of balancing and blueprinting an engine. A balanced engine not only produces more power but also runs smoother and lasts longer. The course provides instruction on how to measure and adjust key components to achieve this balance, including the crankshaft, rods, and pistons.